Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

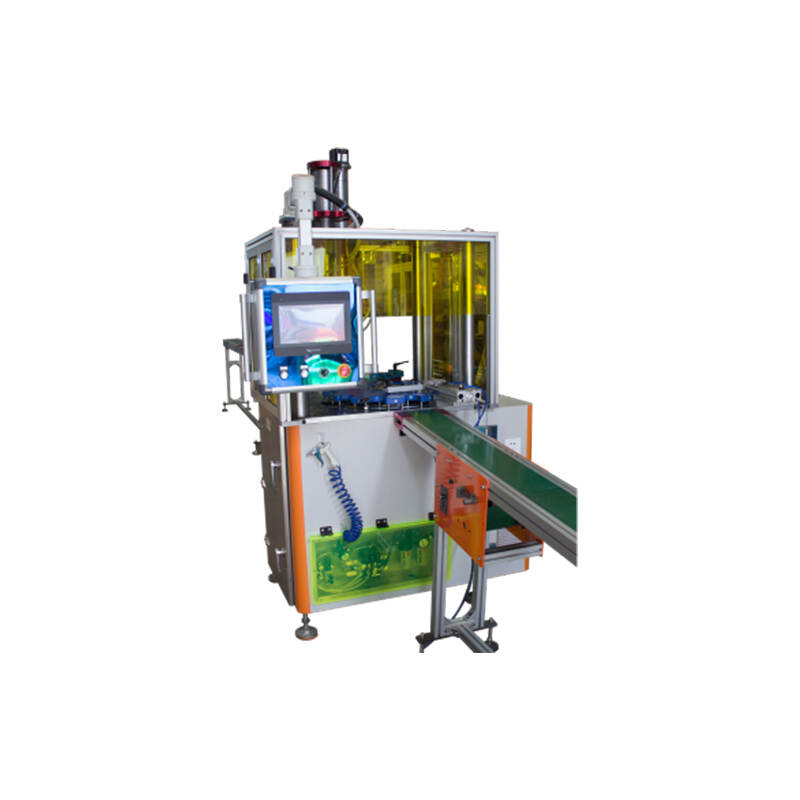

SEFJ-110 Full-auto High Speed Turntable Seaming Machine

The SEFJ-110 full-auto high speed turntable seaming machine is a cutting-edge piece of equipment designed to sew together spin-on oil and fuel filter housings and filter caps. This machine is ideal for factories that need to produce high-volume equipment according to customer requirements.

-

Product Details

Product Introduction

The SEFJ-110 full-auto high speed turntable seaming machine is used for seaming the shell and the sealing cap together of the spin-on oil and fuel filters. It is suitable for the production of rubber spin-on filters and can be used to manufacture laminar, seamless, and corrugated metal filters. The equipment adopts high-speed, high-efficiency technology, with a production efficiency of 30-45pcs/min, which can be customized according to customer needs, such as filter diameter, steel thickness, filter assembly height, etc.

Specification

1.Production efficiency: 30-45pcs/min

2.Seaming diameter: 60-93mm/60-118mm or customized

3.Filter assembly height: 50-270mm

4.Steel thickness: 0.5-0.8mm

5.Motor power: 5Kw

6.Air pressure: 0.6Mpa

7.Power supply: 380V/50Hz

8.Machine weight: 600kg

9.Machine size: 1100mm*800mm*2100mm (L*W*H)

10.Conveyor length: left 6000mm; right 2000mm

Features of Full-auto High Speed Turntable Seaming Machine

1.Advanced control technology, PLC program control, and multi-function touch screen panel operation.

2.Automatic and intelligent operation, easy to maintain.

3.Suitable for the production of rubber spin-on filters and can be used to manufacture laminar, seamless, and corrugated metal filters.

4.German servo motor and Italian pneumatic control system with automatic program speed control unit.

5.Ultra-high-precision surface grinding production process with excellent anti-corrosion effect.

Advantages of Full-auto High Speed Turntable Seaming Machine

1.Long service life:

The SEFJ-110 Full-auto High Speed Turntable Seaming Machine is designed to be durable and reliable, with a low failure rate and a long service life. This ensures that it can be used for years to come, making it a great investment for any factory.

2.Flexible:

This machine is versatile and can be used with different filter materials, allowing for the production of a wide range of high-quality filters. This makes it a great choice for factories that need to produce different types of filters.

3.Electronic induction heating transfer:

The electronic induction heating transfer method used by this machine is ideal for automatic high-speed rotary seam joints of oil and fuel filters. It ensures a strong and reliable seam that can withstand high pressures and temperatures, making it a great choice for factories that need to produce high-quality filters.

4.Adjustable power, speed, and travel via digital controls:

The SEFJ-110 Full-auto High Speed Turntable Seaming Machine is equipped with digital controls that allow for the adjustment of power, speed, and travel. This ensures that the machine can be customized to meet the specific needs of each customer, making it a versatile and flexible machine.

5.Durable:

The surface of this machine is treated with a hardening process, making it durable and able to withstand frequent collisions of materials. This ensures that the machine can be used for years without needing to be replaced, making it a great investment for any factory.