Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

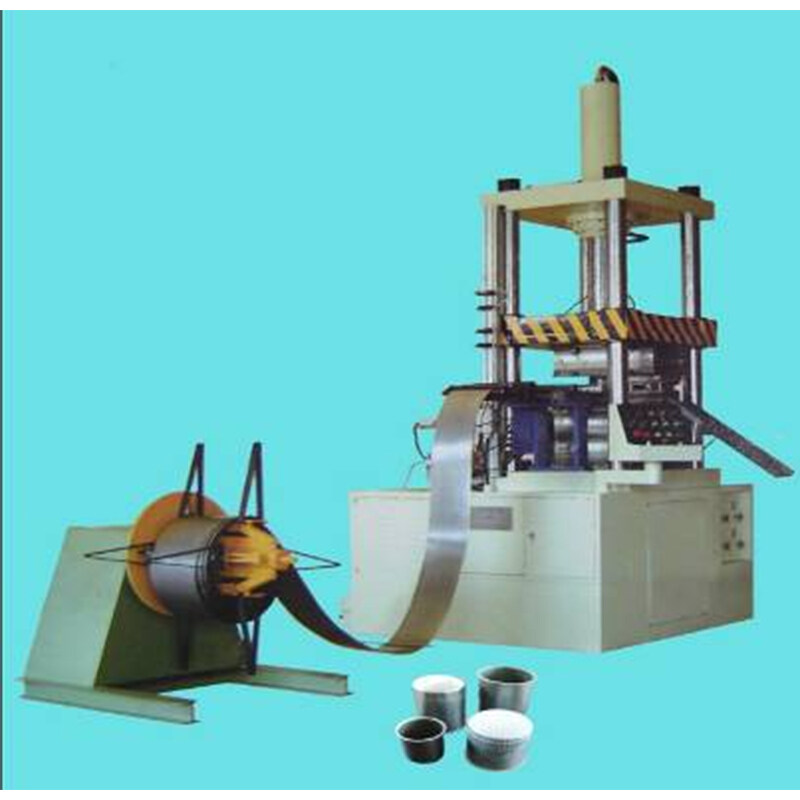

SECZ55-600N Full-auto Servo Knife Pleating Production Line

The SECZ55-600N full-auto servo knife pleating production line is a high-speed automatic servo knife folding production line used to produce filter elements for products like automotive filters, hydraulic filters, and purification filters. The machine features precision electric frequency conversion, speed regulation equipment, and a conveyor for the slitting and marking machines.

-

Product Details

Product Introduction

The machine features a PLC+CPU control system, frequency conversion speed regulation drive, high-precision encoder, brushless electric servo motor, and other advanced technologies for smooth operation, low noise, and low power consumption. The machine can adjust the cutting size through frequency converter speed regulation and cylinder blades of different filter sizes, ensuring high precision and reliability.

Specification

Pre-slitter:

Speed: Adjustable from 0.5m to 12m per minute

Width: Can handle materials from 32mm to 700mm wide

Power supply: 220V/50Hz

Motor power: 0.75Kw

Air pressure: 0.6Mpa

Machine weight: 300kg

Machine size: 1100mm x 1300mm x 1100mm (L x W x H)

Marker:

Max width: Can mark materials up to 600mm wide

Marking distance: Adjustable from 8mm to 55mm

Power supply: 380V/50Hz

Motor power: 0.75Kw

Machine weight: 300kg

Machine size: 1080mm x 750mm x 1100mm (L x W x H)

Pleater:

Max width: Can handle materials up to 600mm wide

Pleating height: Adjustable from 8mm to 55mm

Speed: Adjustable up to 200 pleats per minute

Power supply: 380V/50Hz

Motor power: 0.75Kw

Heating power: 2Kw

Heating temperature: Adjustable from normal temperature to 200 degrees Celsius

Air pressure: 0.6MPa

Machine weight: 500kg

Machine size: 1670mm x 1200mm x 1240mm (L x W x H)

Features of Full-auto Servo Knife Pleating Production Line

1.Accurate and precise cutting: The pre-slitting machine can accurately and freely adjust the cutting dimensions through frequency converter speed regulation and cylinder blades in different filter sizes, ensuring high precision and reliability.

2.Automatic marking: The marking machine can mark in different pleat sizes, and the marking distance can be set freely by the computer screen, ensuring accurate marking distance with the help of the step motor.

3.High-speed production: The machine features a high-speed automatic servo knife folding production line, ensuring high-speed production and increased productivity.

Advantages of Full-auto Servo Knife Pleating Production Line

1.High precision and reliability:

The SECZ55-600N full-auto servo knife pleating production line features advanced technologies for accurate and precise cutting, ensuring high precision and reliability. The machine can adjust the cutting size through frequency converter speed regulation and cylinder blades of different filter sizes, ensuring consistent and accurate cutting every time. This results in high-quality filter elements that meet your specific requirements.

2.Versatility:

The machine is suitable for folding various materials, including iron wire fabric and non-woven fabric of the hydraulic filters, even the multilayer folding. The pleating height, width, and other specifications can be customized according to your specific requirements, making it a versatile choice for your production needs. This versatility allows you to produce a wide range of filter elements, making it a reliable choice for your production needs.

3.High-speed production:

The SECZ55-600N full-auto servo knife pleating production line features a high-speed automatic servo knife folding production line, ensuring high-speed production and increased productivity. This minimizes overhead and achieves operational efficiency and cost savings. The machine automatically creates pleats in a sheet of paper or other material, which are then assembled together to form a filter or air cleaning element (also known as filter media). The machine features automatic tray feeder speeds up production, minimizing overhead and achieving operational efficiency and cost savings. The machine can produce up to 600 pleats per minute, making it a reliable choice for high-volume production needs.