Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

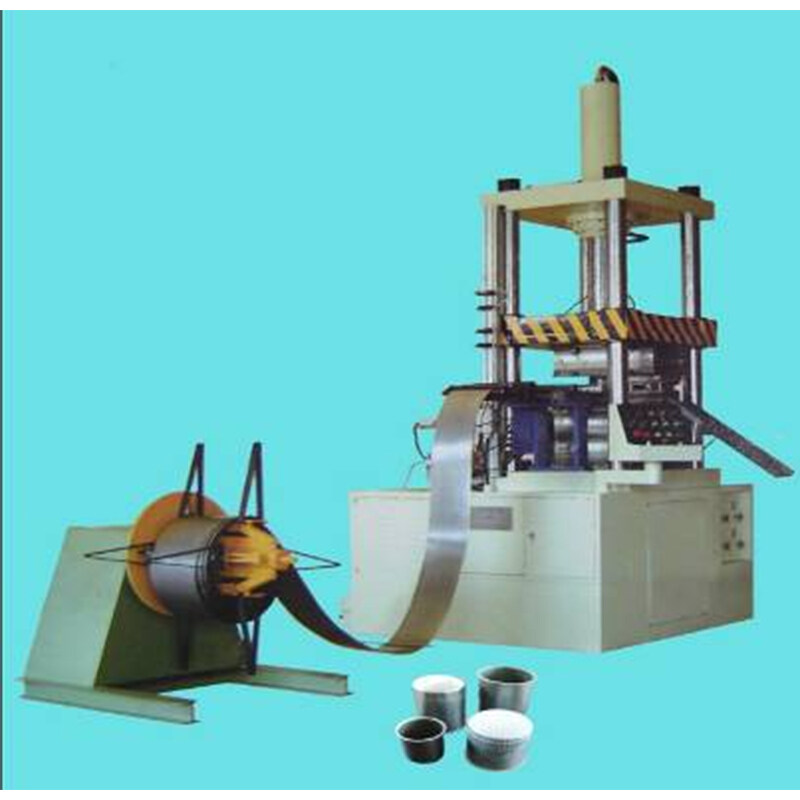

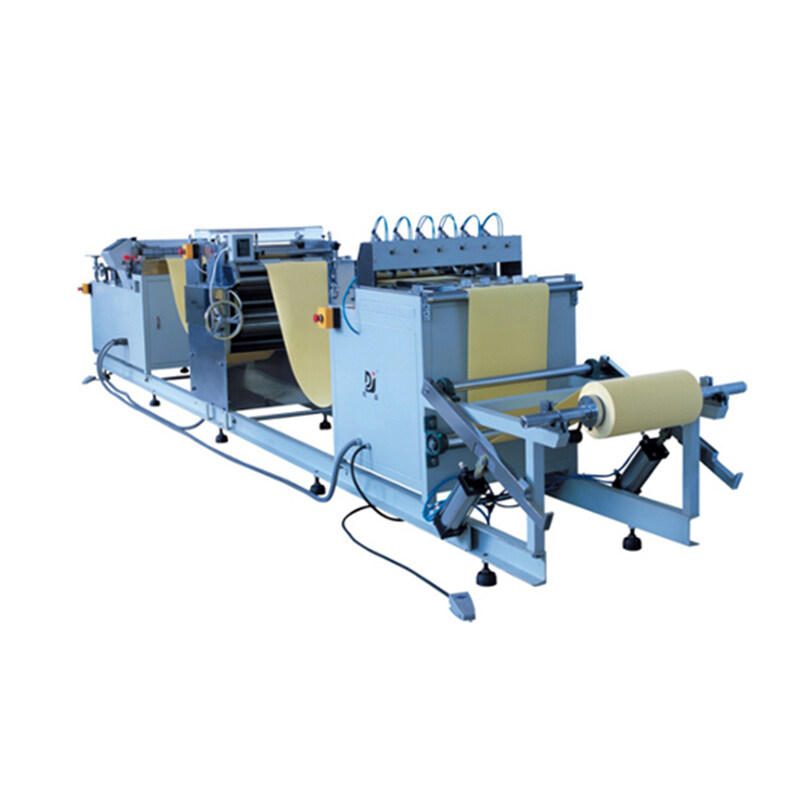

Full-auto Mechanical Press Production Line with Progressive Die

The full-auto mechanical press production Line with progressive die is a machine used in the packaging industry for mass production of various body parts. It is a fully automatic mechanical press with progressive dies that is compact in structure, reliable in quality, and has high production efficiency and convenient operation.

-

Product Details

Product Introduction

The full-auto mechanical press production Line with progressive die is an open-close single-point/double-point press equipped with slide block and progressive die. It is suitable for press molding of substrates/sealing caps and end caps. The machine has two mold installation points, and both points can work at the same time. It is ideal for high-volume production of high-quality elongated, rectangular, and flat films. The machine is also suitable for pressing, forming, and cutting PP/PE/PET bottle caps and aluminum beverage cans.

Specification

1.Nominal pressure: 2000 kN for base plate/sealing cap and 1600kN for end caps

2.Nominal power stroke: 6mm

3.Sliding block stroke: 200 mm

4.Stroke times: 45 S.P.M

5.Maximum mould-installing height: 450 mm

6.Adjustment quantity of mould-installing height: 100mm

7.Distance between columns: 1630mm

8.Dimension of working table plate: Left-Right 2040 mm; Front-Back 760 mm; thickness 170 mm

9.Dimension of sliding block soleplate: Left-Right 1500 mm; Front-Back 580 mm

10.Power of motor: 22 kW

11.Overall dimension: Left-Right 2200 mm; Front-Back 2035 mm; Height 3270 mm

12.Total weight: 21000 kg

Features of Full-auto Mechanical Press Production Line with Progressive Die

1.The fully automatic progressive die mechanical press production line is composed of a mobile base and a die, making it widely used in the packaging industry.

2.There are many models to choose from, including models with Hydraulic Mode/Pneumatic Mode/Hydraulic Mode for multiple sets of workbenches. Continuous mass production is possible.

3.The machine is suitable for the pressing and forming of the bottom plate and the end cover, with two mold installation points that can work simultaneously. It is ideal for high-volume production of high-quality elongated, rectangular, and flat films.

4.The machine is equipped with an automatic die-cutting system and automatic loading and unloading system, making it suitable for stamping on flat materials by four-side cutting machine and 3D forming engraving machine. It can be used to press 3mm thick plastic material.

Advantages of Full-auto Mechanical Press Production Line with Progressive Die

1.Fully automatic:

The full-auto mechanical press production Line with progressive die is a fully automatic machine that allows for continuous mass production, making it highly efficient and cost-effective: The machine’s fully automatic operation allows for continuous mass production, making it highly efficient and cost-effective. This is especially beneficial for businesses that require high-volume production of various body parts, as the machine can produce a large number of parts in a short amount of time.

2.Mass production:

The machine is suitable for the large-scale production of various body parts, including electronic products such as mobile phones, LCD monitors, and hard diskThis makes it a valuable investment for businesses in the electronics industry, as it can help improve production efficiency and reduce costs.

3.Ease of use:

The machine’s compact structure and reliable quality make it easy to use and maintain. Its high production efficiency and convenient operation also make it a user-friendly machine that can be operated by anyone with minimal training. The machine’s robust construction ensures that it can withstand the rigors of continuous use, making it a reliable addition to any production line.

4.Save costs:

The machine is equipped with an automatic die-cutting system and automatic loading and unloading system, making it highly precise and stable in the production process. It also has a low running cost and space-saving design, making it an ideal choice for businesses looking to improve their production processes.This helps to reduce waste and improve the quality of the finished product.

FAQ

Q1:What are the company's main products?

A:The company mainly produces filter equipment, filter accessories and molds,optical screening machine.

Q2:What are the main advantages of the company's equipment?

A:Independent research and development, independent intellectual property rights, customized according to customer needs, affordable price, fast delivery.

Q3:Where can I see a video of the machine in action?

A:The operation video of our machine can be found on YouTube, FACEBOOK and other social media.

Q4: What is the ordering process for equipment?

A:Provide product drawings or photos, list specific size ranges or requirements, and we recommend the most suitable equipment.

Q5:What should I do if the device does not operate after receiving it?

A:We will provide the operation video of the machine, from the first step to all steps of normal production.

Q6:After-sales service and spare parts of the machine?A:We will provide vulnerable spare parts and supporting toolbox at random. If there is a problem in the actual use process, you can take a video of the problem and contact our 24-hour customer service at any time.