Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

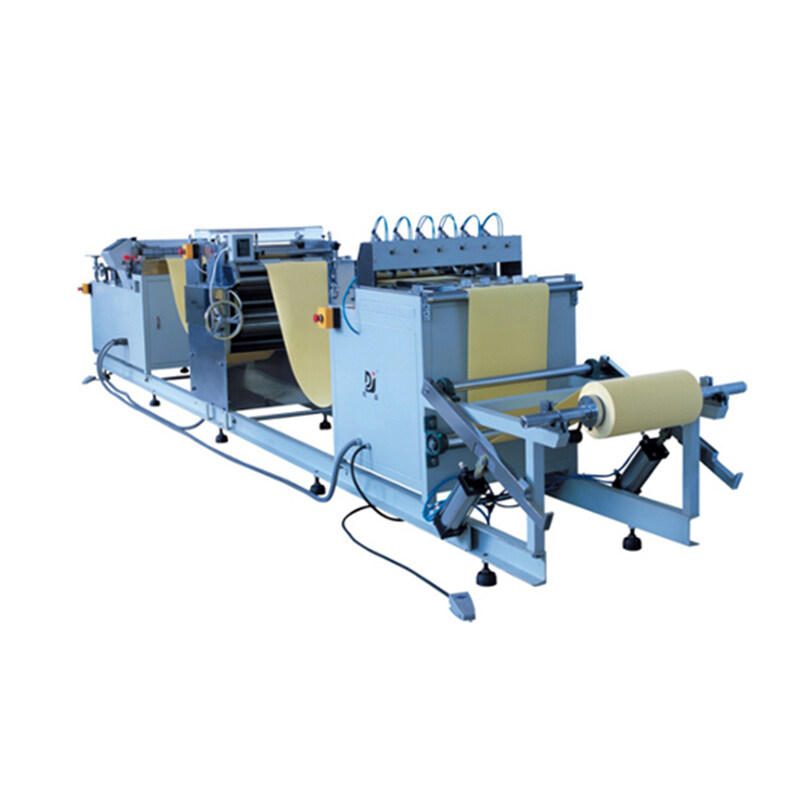

SEWG-630-II Full-auto HEPA Air Filer Mini-pleating Production Line

The SEWG-630-II full-auto EPA air filter mini-pleating production line is a compact folding device that uses cutting-edge mechanical, electrical, and pneumatic technology to produce goods quickly and with high quality. It is designed to produce different specifications of HEPA air filter elements using fiberglass and other filter materials. This machine is widely used in the packaging industry, food packaging, and other industries.

-

Product Details

Product Introduction

The SEWG-630-II Full-auto HEPA Air Filter Mini-pleating Production Line is a fully automatic paper pleating production line that adopts mechanical, electrical, and pneumatic automatic control as a whole. It has high efficiency and stable operation, with an advanced imported servo drive system that ensures reliable operation performance during long-term operation.

Specification

1.Max width of elements: 630mm

2.Production efficiency: 4-22m/min

3.Pleating height: 12-96mm

4.Min dispensing gap: 25.4mm

5.Dispensing lines: 2*24lines

6.Power supply: 380V/50Hz

7.Total power: 15Kw

8.Air pressure: 0.6MPa

9.Machine weight: 2200kg

10.Machine size: 6500mm*1600mm*1100mm (L*W*H)

Features of Full-auto HEPA Air Filer Mini-pleating Production Line

1.The operation adopts the computerization control screen, which is easy to view and operate.

2.The air-expansion shaft is used when paper feeding, also equipped with the tensile force brake control system, which can control the tensile force of paper feeding automatically.

3.This machine is equipped with a paper edge cutting device.

4.The pleating height can be adjusted freely, and the servo control system can accurately ensure pleating neatly.

5.Six options for dispensing: continuously, separately, two sides, one side, auto, and manual.

6.The running speed of the machine can be regulated easily.

7.The pleating height adjusted and the front-back movement of the paper collecting system can be regulated easily and steadily.

8.The convey speed of the system is synchronized by the system through the computer regulation.

Advantages of Full-auto HEPA Air Filer Mini-pleating Production Line

1.High efficiency and stable performance:

Our company has designed and manufactured this machine to ensure high efficiency and stable performance, making it a reliable choice for your production needs.

2.Intuitive and easy-to-operate computerized control screen:

The computerized control screen is intuitive and easy to operate, allowing you to easily control the machine and adjust settings as needed.

3.Precise and accurate automatic press equipment:

The automatic press equipment adopts a servo control system, ensuring precise and accurate operation.

4.Six options for paper output:

With six options for paper output, this machine can easily meet your specific requirements, making it a versatile choice for your production needs.

5.Widely used in various industries:

This sewing and pleating equipment is widely used in the packaging industry, such as food packaging, as well as other industries. It can be used with various materials, making it a versatile choice for your production needs.

6.Fully automatic paper pleating production line:

This is a fully automatic paper pleating production line, with pneumatic and automatic control, ensuring quick and stable production. It has a high production efficiency of 1000 pieces per hour, making it a reliable choice for high-volume production needs.

7.Pinning method of origami for pleating:

The HEPA air filter production line adopts the pinning method of origami to achieve pleating, ensuring high-quality pleats every time.

8.Equipped with safety measures and reliable protection devices:

The whole machine is equipped with safety measures and reliable protection devices, such as an automatic shutdown function in various situations, ensuring safe and reliable operation.